What do you think is the single biggest mistake most beginning rodbuilders make?

What do you think is the single biggest mistake most beginning rodbuilders make?Choosing the wrong blank. And, in my view, it's not just beginners. I'm not talking about the structural integrity but rather the action. If I were to write a book on rodbuilding I would devote a substantial portion of it to learning how to select a good action for the fishing situations the angler will encounter. I grew up fishing a variety of streams for trout and, later, steelhead so my perspective in rod design has always been from a fisherman's point of view. When I started fly fishing in the '50s and '60s virtually all fly rods were designed by anglers who must have fished a lot because most of them were great fishing rods.

After buying Winston in 1973 I tried very hard to continue the tradition of building great fly fishing rods. Winston also had an enviable reputation as a tournament rod maker but I wasn't a tournament caster so my interest wasn't in that portion of the sport. I concentrated on what I knew and the move to Montana in 1976 solidified the choice of just making fly rods for anglers.

A revolution began in the fly fishing industry with Fenwick's introduction in 1974 of graphite fly rods. From the beginning, the graphite rods were stiffer than their fiberglass counterparts. Part of the reason was limitations relating to the mandrel technology and graphite cloth available and part to wanting rods that would cast farther. They also had a more parabolic action because the tips were stiff and in order to get a softer feeling rod they flexed more in the butt than traditional progressive action rods.

The early graphite fly rods, at least for the most part, continued the parabolic type action until the late '70s or early '80s when lighter weight graphite cloth became available, mandrel technology improved allowing for smaller diameter tips, and manufacturing techniques became more sophisticated. In the early '80s I began redesigning the Winston rods to take advantage of these new improvements allowing for traditional progressive action rods, switched to a spigot ferrule from a sleeve, and created rods for lighter line sizes particularly #2- weight and #3-weight.

The typical graphite rods were easier to cast for beginners than fiberglass rods and I think this fact alone contributed to the growth of the fly fishing industry. Along with this phenomena fly fishing was maturing as a sport so there was a proliferation of fly shops, sportsman's shows, and magazines that contributed to the growth of the sport.

I could see one trend occurring with graphite rod design that has continued to the present. The stiff (fast) rod designs predominated with most manufacturers. I have given great thought to the reasons for this and have come up with three postulations: most rod designers must not be avid fishermen so aren't knowledgeable about the best fishing designs, most rods are demonstrated at fly shops where the rod that casts the farthest is equated to being the best, and many anglers go to fly fishing shows where the rod that casts the farthest at the casting pool is the most popular. It's definitely a lot of fun to cast a long distance and graphite rods do that well. However, under almost every circumstance, that's not where the average angler fishes his rods, particularly for trout.

The basic idea of how a rod should work it seems like to me has been lost. For example, rods should be designed so that on the forward cast the rod bends substantially loading the rod (storing kinetic energy) and continues forward under this load until it stops on the forward cast (releasing kinetic energy) propelling the line forward. Under this scenario the angler contributes the casting energy over a relatively long time and the rod does the work of casting the line.

The way that it works with the prevalent stiff (fast) rods is greatly different and this applies to trout, salmon-steelhead, and saltwater rods. It's certainly easy to cast line with a stiff rod witnessed by Lefty Kreh casting with a broomstick with guides attached. However, this requires the angler to do an extraordinary amount of casting effort because he is now doing substantially more of the work over a shorter period of time. On bigger rods I have seen this cause shoulder problems and tennis elbows.

So after this discussion about some of the history rod action how should a builder go about choosing a blank?

The first decision would be are the current rod designs and line designations correct or, as I say, are they too stiff (fast)? Let me make one more pitch that they are too stiff. From my observations Winston's older graphite rods that I designed were softer, or flexed more, than the typical rods from other companies other than Scott. In the late '80s I brought out the Tom Morgan's Favorite that is an 8' #4-weight rod that, even by Winston's standards, was softer than the normal graphite rod being a #3 �- or #3 �-weight rod. Anglers love this rod and for many years it was Winston's most popular rod and, still, I hear from anglers how much they love this softer action. I have talked with so many anglers over the years who love the softer rods and wonder why the rod companies still continued to make stiffer rods that I very strongly believe that I am correct.

The second decision is to rigorously determine how the rod is going to be fished and the distance that it will be fished. This distance should be laid out on a lawn or other area so that you can cast the rod at that distance. I think that in today's market with so many rod line designations being questionable that it's crucial that the rodmaker cast a finished rod of the blank that he intends to use. With very great determination resist casting your trial rod at a distance greater than your standard long cast and spend most of your time casting the distance on either side of your average cast. I would try two or three different lines on the rod to determine which line size feels the best.

I think that I should add one observation here. Many of today's fast rod designs have what I think is good action if they are loaded properly so that they bend and flex as I think they should. Just because they are fast doesn't necessarily mean that they are bad designs from a taper standpoint.

For many years I was a strong advocate of a rod receiving a single line size designation. For me, that is still true because I like a rod to have a certain feeling and only one line size will give me the feeling I like. However, I now believe that rod companies should have a rod designated for at least two line sizes and, in most cases, three line sizes. Why? If, as I say, the rods are for the most part too stiff for their designated line sizes this would give the angler permission to use a different line. This might seem like a minor point but, I assure you, it's not.

If, for example, you and I were to cast a #4-weight rod that both of us, after trying several line weights on it, agree that we think should carry a #6-weight line most anglers would feel that by over-lining the rod two line sizes they would be damaging the rod. Many also would believe by going against the manufacturer's recommendation they would be making a mistake so they wouldn't do it. (This might seem like a ridiculous suggestion but I assure you that, from my experience, it's not). Well, you would be going against the line recommendation but, I assure you, you won't damage the blank. That rod would have the same amount of material and structural integrity of a #6-weight blank that I would design. This seems like a hard stretch for most anglers to accept that I have talked with about rod line designations.

There is one additional item that I would like to mention. Before fly fishing became so popular and so many rod companies got into the sport new rod designs came about because of a need for a better fishing rod. Sadly today many of the designs seem to me are driven by the need for companies to come out with new products to maintain sales or market share and have little, if anything, to do with being an improved fishing rod. In your rod selection try to stay away from Madison Avenue hype and determine which rod design is going to best suit your fishing needs.

What advice would you have for those thinking about getting into building rods as a part time or full time source of income?

What advice would you have for those thinking about getting into building rods as a part time or full time source of income?

Part time ok and full time very questionable.

Building rods can be a very rewarding occupation as I have found but a difficult one to make much money pursuing. By doing it part time you can provide customers with rod actions that they may not be able to find with factory produced rods and certainly you can provide components that are unavailable to customize or enhance the value of a rod. You can often charge more for a custom made rod than a customer would pay for a factory produced one providing the maker with a reasonable profit. However, what I often see is a custom builder charging less than a factory-produced rod. I would certainly resist doing this. Don't forget that you are providing a good service and product.

Probably the most rewarding aspect of my association with the rod business is the people that I have met. By offering custom rods you develop close ties with customers who eventually become friends and fishing companions. By building rods part time your overhead is absorbed into your house or shop so you don't have to do a real accounting of the costs. It can provide some extra money to pay for fishing "research" so essential to rod building.

I think that going into rodmaking as a full time business is very risky. Perhaps fifteen or twenty years ago it wouldn't have been so but today it's a different story. Since the advent of Chinese and Korean rods into the marketplace with their very low retail price you are competing with unfair competition. I say unfair because they are never going to support our streams or our fisheries. Their rods are strictly commodities where the lowest price wins and the consumer beware. Also, you are competing with American manufacturers who warrant their rods with a lifetime guarantee against anything including abuse. This has dramatically changed the marketplace against the smaller manufacturer. I have been able to resist this because of my reputation and very high value products sold to customers willing to pay a high price for exceptional designs, fittings, and workmanship.

What direction do you think rod construction is going and what is the next "big thing" in rod building?

I am not a good student of current ideas for the future designs and techniques of blank manufacturing so I'm not the best to offer an opinion in this area. From what I see the technologies will remain as they are for the near term. There may be some small innovations but I don't see a dramatic change like occurred with the advent of composite materials and current mandrel/manufacturing processes. It seems that the industry is headed towards producing cheaper rods.

As a rodsmith, what is the achievement that you are most proud of?

I have always been very proud of the work that I did at Winston. I feel that I was one of the people that drove the industry to upgrade the quality of the rods and fittings.

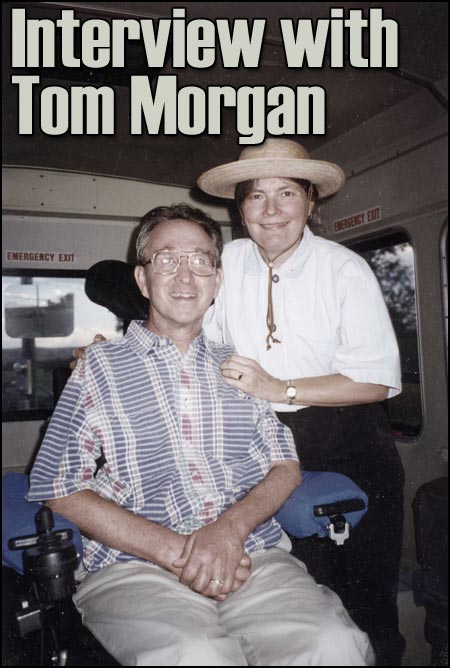

For the last number of years that I was an owner of Winston I had a dream of creating the ultimate fly rods regardless of cost. I feel very strongly that my wife, Gerri, and myself have achieved this goal. The rods that we are building are great fishing rods and the components and workmanship are the very best. I think it takes a long time to be able to see what goes into all of the detail that comprise an exceptional rod and I have spent the time to learn those details. Having the vision and tenacity to build these great rods has been my biggest achievement

Some people question what seems our high price of $1145 and $1195 for a graphite rod. I happen to think that they are too cheap and people are getting a great value. I remember buying a Russ Peak fiberglass rod in 1974 for $250 when a Winston fiberglass was $65. An equivalent Winston graphite rod today is in the $600-700 range so based on the same relative value ours should be in the $2500 range.

One thought that Gerri and I have about the rod business is that we don't want to sell disappointment in any form and work very hard not to do so.

You didn't ask what the second most important achievement was so I'll mention it because it's very important to me. By making great fishing rods both at Winston and Tom Morgan Rodsmiths I have brought a lot of enjoyment to anglers who enjoy the rods on their favorite streams. And it's always been very rewarding to me for them to share their love of the rods and their appreciation of them.

What is the one place on earth that is your favorite place to fish?

Sorry, a double answer here. My favorite steelhead stream is the Morice River in British Columbia. It's a medium sized river with clear water, wild fish, solitude, and lots of steelhead. It's also a great dry fly stream. I fished it for a number of years only on my terms of using dry flies and was very successful. The fish don't run very large, mostly four to ten pounds, so I could use my 9 �' #6-weight graphite rod. It's also an interesting stream because you see lots of pink salmon, many king salmon, bears, eagles, and an occasional wolf.

My favorite trout stream would be the Beaverhead River just upstream of Dillon about � mile on the Herb Wheat Ranch. The main river on the ranch is about a mile long and there are two shorter channels that have over the years provided exceptional fishing. It has a variety of waters from shallow riffles to flat water and deep pools. It's not a big river averaging probably forty feet wide. This particular stretch of river has lots of insect hatches much of the year. I started fishing it in 1968 and fished it almost every year for 25 years. During that time I probably guided on it or fished it over 200 times. You probably won't believe this but I saw one wading angler, three anglers float by in a boat, and one vehicle parked but never saw the anglers in 25 years! I'm afraid those days are gone forever. It's now available as a fee fishing place. I was there last year and saw lots of rising fish so I know its still good fishing.

I noticed the beautiful reel seat hard ware you have on your rods that I don't think I have ever seen on the market, is this hardware something you make or have made especially for your rods?

I noticed the beautiful reel seat hard ware you have on your rods that I don't think I have ever seen on the market, is this hardware something you make or have made especially for your rods?The hardware is made special just for our rods. When Gerri and I started the project we wanted everything to be special and unique. Gerri wanted the rod tube to have the look and feel of an old-time walking cane. We were visiting my cousins Bob and Robert Hodge of Grants Pass, Oregon, who now make the rod tube cap and collars for us and we were all talking about different design concepts with their designer, Dennis Detloff. Dennis knew what we were looking for and sketched out a preliminary cap and collar design. His training was as a gunsmith and immediately suggested that we use an octagon shape for our tube. Dennis then sent us drawings for our octagon rod tube, cap, and collar that we adopted.

An interesting sidelight to the design is that I wanted the cap to be long enough so that the rod in its bag could stick out of the tube about an inch so that anglers wouldn't have to reach into the tube to grab the rod. I added this design and it works very well except that everyone wants to try and shove the rod all the way into the tube because that's what they are used to doing.

Gerri and I wanted everything to be as color coordinated and design coordinated as we could. Therefore, I designed both a slide band and uplock reel seat that matched as closely as I could the rod tube cap and collar incorporating an octagon cork check and an octagon winding check. On top of the rod tube cap is a silver minted coin of our logo outlined with a brass ring. This is replicated on the bottom of the reel seats with an engraved logo and brass ring.

Over the years I learned what makes a beautiful nickel (German) silver reel seat. The machining must be absolutely first rate so as to minimize or eliminate tooling marks, the parts have to be sanded with very fine paper or tumble polished, and then must be buffed to a perfect and flawless luster. From my experience, this is very difficult to accomplish and not many people seem to achieve perfection. It takes an unrelenting sense of purpose to achieve and an attitude that good enough never is. We get our reel seat parts from Struble Manufacturing in Oregon who I have done business with for a long time. They have been very accommodating in helping achieve our unique designs and they are able and willing to achieve the flawless workmanship that I demand.

The wood I have collected over the years or we buy from specialty suppliers. Most of it is stabilized with resin because we ship many of our rods to humid climates and want the wood to be as stable as possible. We do the wood turning, slotting, finishing, and cutting to fit the metal parts ourselves.

I see on your graphite rods that you use agate stripper guides. Do you find them durable enough for modern lines/techniques, and do you see any drawbacks to using them?

I see on your graphite rods that you use agate stripper guides. Do you find them durable enough for modern lines/techniques, and do you see any drawbacks to using them?Actually our graphite rods use an agateen stripping guide that is glass whereas the bamboo use true agate. Both the agateen and agate are very hard and durable with the agate being somewhat harder. There is always the risk of them being broken with a hit but so far we haven't had any break. Either doesn't dissipate heat really well but on trout rods I don't see that as a problem since there isn't a lot of pressure put on the guides. Under salt water conditions heat could build up and damage a line. The reddish color of the agateen matches our blank color along with the thread color so altogether they make a beautiful combination. The subtle agate colors complement the bamboo rods. And both are traditional so appeal to me.

What is your opinion on contemporary fiberglass rods? Does fiberglass still have any valid performance advantages? Under what conditions would you suggest a glass rod and what would that glass rod be like (length, action, weight, etc..).

To be straightforward I haven't cast any of the new fiberglass rods. I am reluctant to mention what I am going to because it's personal but necessary as an explanation. I am almost totally disabled with MS and can't move my hands or arms for casting. I don't mention this for sympathy but only as an explanation. One thing that might be of interest is that I am answering these questions myself using DragonDictate voice-activated software. It's wonderful and has greatly improved my life because I can totally run my computer with it. I have a great life with Gerri and fortunately don't think of myself as being disabled. Our graphite rods I designed when I could still cast. The bamboo rods I designed and had people cast them who I trust to give me honest straightforward comments and who I know from previous experience like the same type of action that I do.

Fiberglass rods do still have a place in some situations. As I explained above many of the current graphite rods are fast so anglers looking for a softer rod could find it with some of the new fiberglass ones. Generally speaking, fiberglass lends itself to shorter and lighter weight rods. There is a characteristic of fiberglass material that needs to be explained as compared to graphite material.

When fiberglass is made into a rod it has a unique loading property. As it bends under a load it continues to resist the load until it reaches its maximum load bearing capacity then it will continue to bend but won't carry a greater load. This allows the rod to work well in the short to medium ranges but as the load increases it becomes more difficult to cast long distances. Graphite is just the opposite. It will continue to accept a load and resist bending until it deflects so much that it fails catastrophically. This is one of the characteristics that make graphite such a versatile and satisfactory rod building material and allows designers to create designs that work well over a large range of casting distances.

Fiberglass is also heavier than graphite so when it is made into a rod it's more like bamboo in that the weight of the material will help load the rod and may provide a rod that feels smoother.

I also think that fiberglass is often overlooked as a great rod building material for bigger rods. Let me explain. It certainly is somewhat heavier but not so heavy as to be uncomfortable except in the biggest rods. I alluded to the fact in the first question that stiff rods need to be loaded faster and this can cause shoulder and elbow problems. The difference in loading time between casting a slower rod like fiberglass and a stiffer graphite one is only a few fractions of a second but it's long enough that with the slower rod it's smoother and easier to cast. There again, you are loading the rod over a longer period of time and they develop the smoothness that makes casting a joy.

As you all know I have cast a huge number of different rods in bamboo, fiberglass, and bamboo. Of all of those thousands of rods there have been, perhaps, ten absolutely fabulous rods and two of those have been Winston fiberglass rods: a special streamer rod that I made for myself that is an 8' 3" #6-weight and an 8' 6" #7-weight that I call the unity with the universe rod because it's so perfect.

What are some specific things you look for in designing your rod actions (both graphite and bamboo)?

What are some specific things you look for in designing your rod actions (both graphite and bamboo)?Four characteristics: correct line size by my fishing standards, progressive action, smoothness, and consistency of action between models. I will talk some about each characteristic.

At the risk of sounding like a broken record on the subject I am extremely careful in making sure that the rods bend and flex the correct amount for the distances that I believe they will be fished. It's extremely satisfying when someone casts one of my designs and you can almost see a light go off in their head reaffirming that they think it's just the rod they want for their fishing.

I have always liked the progressive style action. I certainly understand that this design isn't always the very best for every situation but for trout rods I believe that it's the best all around design. With a light and supple tip, like my designs have, you can fish close off the top portion of the rod and you will feel the rod bend. Then, if you want to cast a longer distance, you have the power in the butt to support the cast. Also, the supple tip allows you to form a narrow loop that penetrates the air well for your distance cast. In addition, the lighter tip lets you hook fish easily on light tippets without breaking them off on the strike and to play fish with authority while protecting the tippets from breaking. One added benefit if you are fishing a stream that is brushy the supple tip allows you to partially "fold" the tip back and drive a very narrow, tight loop under overhanging brush where the biggest fish often hide.

One of the most important characteristics of any fly rod is how sweet it feels in your hand when you are casting. I believe that this sweetness comes from having the rod in perfect balance between the tip and the butt and that the progressive taper is smooth as it progresses down the rod. All of my current designs have this smoothness. I think that it's important to talk about it in reference to today's typical graphite designs in particular.

Almost all of the modern graphite rod designs are a tip over butt ferrule. The butt, that is smaller in diameter and thick walled, fits inside a tip, that is bigger in diameter and thin walled. It's not impossible to design a smooth casting rod with this configuration but it's nearly so because of the inherent difference in weight and flex. The rods are made this way for manufacturing reasons in order to save money and increase production because you don't need an actual ferrule. You also don't need special mandrels to manufacture parts to include a ferrule mounted on the rod or to install a spigot ferrule like the older Winston or Scott designs. By making complex cloth patterns you can help smooth out the transitions but they are never perfect.

The Tom Morgan Rodsmiths rods have a female ferrule rolled on the tip so that even though they look like the typical graphite designs they are not. If you were to extend the butt of the rod to where it meets the tip the outside and inside diameters match perfectly as does the amount of cloth. The rods with a spigot ferrule are usually the same. For many anglers this isn't a big consideration but for me it is because my goal in rod design has been to make the most perfect rod regardless of cost or efficiency.

When I used to go to sportsman's shows I always spent some time at other rodmaker's booths casting a variety of their rods. It was always surprising to me that within a model group that their actions would often jump all over the place in feel. I could never understand that. One important goal that I've always strived for is consistency of feel between rods. In the past, and now, many of the rods are sold long distance without anglers having the opportunity to cast them before buying. Almost all of the anglers are familiar with my designs and action so they can order rods with confidence that they will feel like previous designs. They also have the confidence that if they buy a #3-weight rod it will have the same flex pattern and feel as a #6-weight rod except that it will balance the lighter line.

What should a bamboo rodmaker look for when designing a taper?

What should a bamboo rodmaker look for when designing a taper?

I think the same parameters that I discussed in question #9. The exception to this would be whether or not you preferred the progressive action or another such as the parabolic like Paul Young produced. There are lots of different tapers and actions. The beauty of bamboo as opposed to other materials available to the average rodmaker is that you can generate any taper that you would like based on rods you have cast or old masters. It's just a matter of miking the taper and replicating it. The only exception would be with hollow rods of one sort or another.

How do you match a rod action/taper to an individual's casting style?

This is a difficult question for me because I have always designed rods for my preference with the hope that many other anglers would agree with my thoughts. I realize that the progressive style action with a supple tip is the most difficult rod action to cast well. However, I have always designed what I thought was the best action regardless of the rod's difficulty to cast with the assumption that the angler was either a good caster or they would become one. As custom rodmakers I realize that you may be not be the case for you and that with the broad variety of rod blanks available that you might want to customize a rod to a particular angler's casting and fishing preferences.

As a general rule beginning casters, along with some intermediates, have the tendency to rush the forward cast applying power too early in the stroke. The casting maxim for either the back stroke or the forward stroke is that if too much power is applied before the rod tip passes 12:00 o'clock you will tail the loop. As a result of this premature power stroke and tailing of the loop the cast isn't smooth and the line doesn't go out well. A parabolic action rod or one with a stiffer tip will help prevent the tailing loop. As an aside I think that the stiffer graphite rods have helped anglers learn to cast even though they aren't the preferred action for most fishing conditions.

I would think that the best approach would be to have several rods with different actions and have the prospective angler try each. Along with these trials I would query them carefully about their angling conditions and how they see each type of rod satisfying their demands. It's really up to the angler but with your experience you should be able to guide them in the correct direction. Depending on your situation having sample rods they could actually fish would also be a good option.

Do you find yourself most often fishing graphite or bamboo when on the water and why?

Towards the end of my fishing I fished graphite most of the time. In fact, the Tom Morgan's Favorite 8' #4-weight was not an advertising gimmick; it was the rod I used for at least 50% of my trout fishing.

Why? Well, to begin with, the graphite rods I designed and used were great fishing rods. For someone who loves fishing and particularly rods I was in the enviable position of being able to design and then use exactly what I thought would make the best rod for a particular situation. I was fortunate in my thought process of designing rods to be able to conceive of a design mentally and to know exactly what I wanted it to do and how I wanted it to feel before I began.

In addition to being great rods graphite were also easy to fish day in and day out under a variety of conditions. I would often catch good-sized and robust fish on light tackle in Montana and with graphite rods I didn't have to be conscious of playing the fish with care in order to not damage the rod. Since my steelheading days where I caught large fish on light tackle I had learned to play fish very aggressively without breaking the light leader in order to get the fish in quickly tiring them the least amount possible.

I would also use bamboo rods on special occasions or on special streams where I thought they were appropriate. In addition, I also had a couple of fiberglass rods that I enjoyed using a lot. I have always liked streamer fishing and for my technique it required a very special rod with a soft and supple tip to move the fly effectively. The special streamer rod that I made was perfect for my technique. For those interested you can read my article on streamer fishing on our web site at the URL: http://www.troutrods.com/morgantwitch.html My method of streamer fishing is extremely effective on all types of water but difficult to accomplish.

It wasn't always this way. In the beginning of my fly fishing I started with fiberglass rods in the '50s and in the early '60s I acquired several bamboo rods and fished with them exclusively until I bought Winston in 1973. After buying Winston and developing different rods I fished a variety of materials depending on which rods were my favorites at the time.

What are some of the advantages of the Morgan Handmill and why should a part time rodmaker who is not mass-producing consider investing in one?

Whether you are a beginner or an experienced rodmaker you will be able to produce strips that will always have the correct angle because it's fixed with the cutter head, have good sharp edges, and clean cuts along their entire length. It is easy to set up, straightforward to operate, and provides strips that are very accurate and consistent in size. In talking with lots of bamboo rodmakers they also think that it's considerably faster to use than hand planing for several reasons. When you are making your cuts you are cutting both sides at once, there are no planes to sharpen, you virtually never lose a strip with a bad cut, and you can just make your cuts without checking your strips.

It's also a very versatile machine allowing you to make swelled butt rods with an accessory that comes with the Hand Mill, you can cut either 8-, 6-, 5-, or 4-strip rods just by changing the cutter head which takes just a couple of minutes, and with an accessory you can hollow flute your rods. Another aspect that many rodmakers like is that you are using your big muscles when cutting and not your wrist as with a hand plane.

However, I certainly know that you can make excellent bamboo rods using a planing form and purchasing the equipment is considerably less expensive. If you plan on making just a few rods then for many rodmakers the cost isn't justified. Some rodmakers do enjoy using equipment that represents a new approach to rodmaking and the ease of use and quickness of cutting strips allows more experimentation with different rod tapers and actions.

One advantage to the Morgan Hand Mill is it allows the user to make quad or penta rods just as easily as a hex. Given the relative ease of construction, what is your take on quadrate rods in general? Specifically regarding performance vs. hexagonal cross-section bamboo rods.

I don't have enough experience with either quad or penta rods to offer an opinion. One rodmaker who I greatly respect for his knowledge of rod tapers and actions, Per Brandin, likes quad rods a lot so based on his experiences I would think they offer a good alternative to hexagonal.